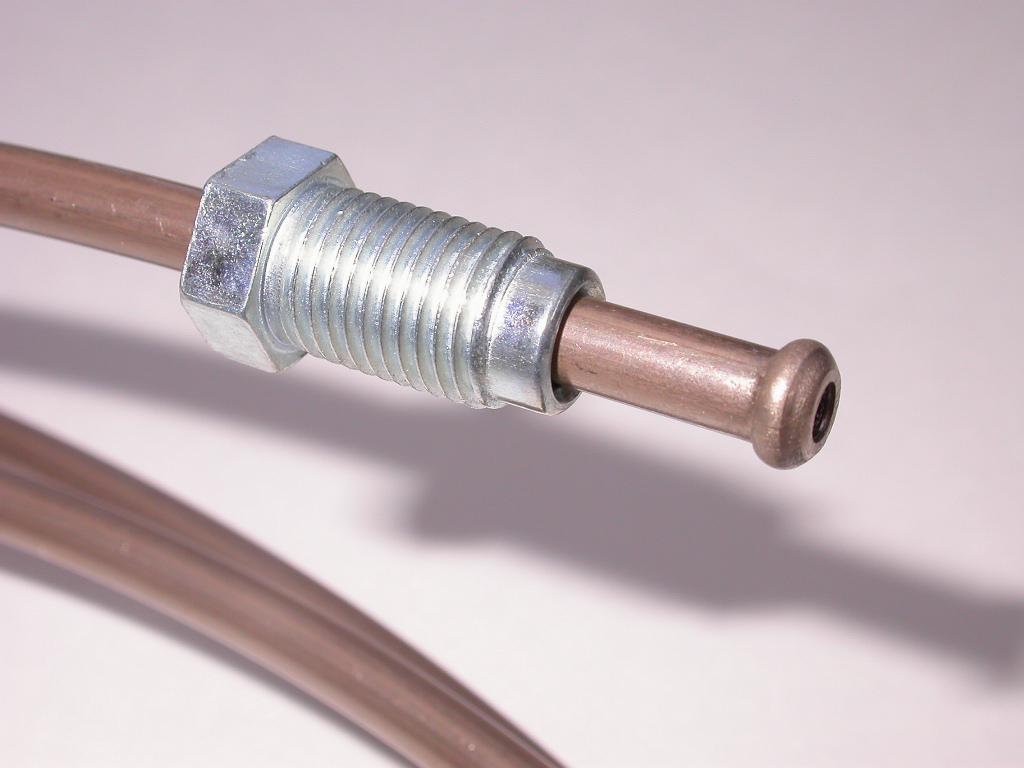

Cracked Brake Hose

How to repair the brakes on your Ford truck. NOTE Photos to be added soon. This repair is front disc brakes only, not rear drumsdiscs. Tools needed Sledge hammer. Regular hammer. WD4. Pry barlarge flat head screwdriver. Extra large plumbing pliers adjustableBrake kleen spray or similar degreaser. Anti seize compound such as Never seezeLug nut wrenchiron. Hydraulic jack stands. Paper towels. Newspaper. Drain pan or oil drain container. Mask if desired. Procedure Loosen the lug nuts on the front wheels dont remove. Lift the vehicle by the large cross frame member between the. Use a couple 2x. 4s on top of. Place two jack stands on the ends of the frame member in case. Lower the vehicle so it places. Leave hydraulic jack in place. Find out why you should get your Auto Repair done at Westside Auto Pros in Des Moines, IA. P. O. Box 16 13550 Three Oaks Rd. Sawyer, MI 49125. Neat Stuff For Corvettes. C1 to C7 Only Corvette Central has it all mailcorvettecentral. Troubleshooting Bleeding Difficulties. If you are having difficulty getting all the air out of the system or you are not obtaining a firm pedal, try these steps to. Remove the lug nuts and pull off the tireswheels. Wear your respirator mask for brake dust which may contain. Put some newspaper down below each brake assembly to catch rust. Makes for easier cleanup. Use the 1. 3mm wrenchratchet to undo the two caliper slide. Pull the caliper off the disc rotor and. Do not hang it by the hydraulic. Use the 1. 8mm wrenchratchet to remove the two large bolts that. You may need a hammer to pounds your. Then remove the whole bracket. Cracked Brake Hose' title='Cracked Brake Hose' />The Car Care Council has developed a service interval schedule with general guidelines for the regular maintenance of passenger cars, mini vans, pickups and SUVs. Brake Rotor Identification. Editors Notes Volvo 700900 series brakes came in a number of configurations onepiece hub and rotor versus separate rotor and hub. Cracked Brake Hose' title='Cracked Brake Hose' />

Use a flat head screwdriver or your prybar to pull out the old. Leave the anti rattle clips in the disc retainer bracket as they. If they are cracked replace them with new ones. With everything removed and the disc rotor accessible it. It definitely does not pull off. Put the. little straw type tube on your WD4. Look at your new replacement rotor to see where. Then rotate it and spray every so often on the. Now spray into the tiny space between the wheel lugs and the face of. Let it soak a few minutes. Turn the rotor to let the WD4. Take your regular hammer and give it a good smack between the. Sometimes this is. You will hear the clang change when it dislodges. The rotors are usually very stuck. Next take your sledge or. Either turn the rotor or change your. If it still doesnt move go again liberally with WD4. Let it soak. Work on the other wheel. Looking at the disc rotor assembly, on the rear side or the. Rotate the rotor and smack it in a few places. This. should dislodge it. Keep rotating the rotor and smacking it to get it off. Dont damage the lug threads though. Dont hammer too hard or you may do. Place a drain pan under the brake assembly to catch the. Apply some anti seize compound. Dont go too thick here. Thin. like paint only. This will make it much easier to pull the rotor off the next. Pull your new rotor out of the box and spray both sides of the. Use clean paper towel. It should dry fairly quick. Set it aside. Place a larger wrench across the face of both pistons in the. The level of brake fluid will rise, take care not to overflow it, you. Its tough, use your muscles to compress the pistons. Otherwise use two large C clamps if you have them or one with a wrench across. This is the preferred method. Be careful as you can chip the. American Cancer Society Ride Program here. They are made of a composite material. Now mount the cleaned new rotor on the hub. Hold it on with a. Remount the disc retaining bracket with the 1. Apply. anti seize to the bolts so these will be easier to remove next time. Tighten. them good Apply anti squeal shims to the backsides of your new brake. Mount the pads into the retaining bracket. Make sure that you. No harm done in having both squealer pads on one. The inner outer pads are. Squeeze the pads together with your fingers so its easier to mount. Pull the rubber boots back on the caliper. Move the caliper slides back and. Cover the slides with the rubber. Take the caliper off the wire hanger you used to hold it up in. Make sure the pistons are fully depressed into the caliper. Slide the caliper over the pads and into the retaining bracket. Watch. to make sure the caliper fits over the pads including the anti squeal shims Fasten the caliper with the 1. Remove the nuts from the lugs if you used some to hold the. Bleed the. brakes. See article on this site. Remount your wheeltire assembly and torque the nuts down in a. Test the feel of the brake pedal, should be same or better. Take the vehicle for a test drive. Make 8 gradual stops from. Dont slam the brakes on. Do this by your house if you can. Park the vehicle after these break in stops and let the rotors cool for at. This will ensure your. Check your wheel lug nut torque again. Clean up the mess. Re torque your lug nuts after 5. See the article on Brake Bleeding. Youre done. Congratulate yourself on having saved at least 3. Thanks to. Peter Ferlow for.

Use a flat head screwdriver or your prybar to pull out the old. Leave the anti rattle clips in the disc retainer bracket as they. If they are cracked replace them with new ones. With everything removed and the disc rotor accessible it. It definitely does not pull off. Put the. little straw type tube on your WD4. Look at your new replacement rotor to see where. Then rotate it and spray every so often on the. Now spray into the tiny space between the wheel lugs and the face of. Let it soak a few minutes. Turn the rotor to let the WD4. Take your regular hammer and give it a good smack between the. Sometimes this is. You will hear the clang change when it dislodges. The rotors are usually very stuck. Next take your sledge or. Either turn the rotor or change your. If it still doesnt move go again liberally with WD4. Let it soak. Work on the other wheel. Looking at the disc rotor assembly, on the rear side or the. Rotate the rotor and smack it in a few places. This. should dislodge it. Keep rotating the rotor and smacking it to get it off. Dont damage the lug threads though. Dont hammer too hard or you may do. Place a drain pan under the brake assembly to catch the. Apply some anti seize compound. Dont go too thick here. Thin. like paint only. This will make it much easier to pull the rotor off the next. Pull your new rotor out of the box and spray both sides of the. Use clean paper towel. It should dry fairly quick. Set it aside. Place a larger wrench across the face of both pistons in the. The level of brake fluid will rise, take care not to overflow it, you. Its tough, use your muscles to compress the pistons. Otherwise use two large C clamps if you have them or one with a wrench across. This is the preferred method. Be careful as you can chip the. American Cancer Society Ride Program here. They are made of a composite material. Now mount the cleaned new rotor on the hub. Hold it on with a. Remount the disc retaining bracket with the 1. Apply. anti seize to the bolts so these will be easier to remove next time. Tighten. them good Apply anti squeal shims to the backsides of your new brake. Mount the pads into the retaining bracket. Make sure that you. No harm done in having both squealer pads on one. The inner outer pads are. Squeeze the pads together with your fingers so its easier to mount. Pull the rubber boots back on the caliper. Move the caliper slides back and. Cover the slides with the rubber. Take the caliper off the wire hanger you used to hold it up in. Make sure the pistons are fully depressed into the caliper. Slide the caliper over the pads and into the retaining bracket. Watch. to make sure the caliper fits over the pads including the anti squeal shims Fasten the caliper with the 1. Remove the nuts from the lugs if you used some to hold the. Bleed the. brakes. See article on this site. Remount your wheeltire assembly and torque the nuts down in a. Test the feel of the brake pedal, should be same or better. Take the vehicle for a test drive. Make 8 gradual stops from. Dont slam the brakes on. Do this by your house if you can. Park the vehicle after these break in stops and let the rotors cool for at. This will ensure your. Check your wheel lug nut torque again. Clean up the mess. Re torque your lug nuts after 5. See the article on Brake Bleeding. Youre done. Congratulate yourself on having saved at least 3. Thanks to. Peter Ferlow for.

Latest Pages

- Gta Vice City Zombie Mod Full

- The Most Beautiful Woman In Town Charles Bukowski Pdf

- What Would Emma Do Pdf Creator

- Meade 4.5 Computerized Telescope Manual

- Boot Disk For Windows Vista Usb Drivers

- K-Lite Codec Pack Z Coreavc

- Warehouse Management System Project In Java Free Download

- Uae Sharjah Zip Code

- Uninstall Far Cry Patch

- Hp Compaq Nc8000 Wifi Drivers

- Cost Per Roll To Install Wallpaper Youtube

- Transdermal Vitamin B12 Delivery Patch

- Cal Patch Folk Blouse

- Heros 3 Mf

- Vinod Rathod All Mp3

Copyright © 2017 Cracked Brake Hose.